FABRICATION SERVICES

From the moment you engage RLE systems to visualize your concepts and ideas we will utilize computer aided design to realize these ideas into a usable drawing.

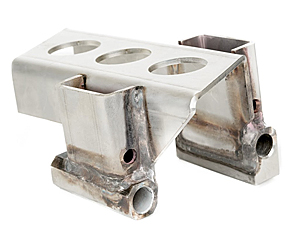

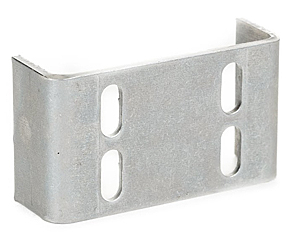

FABRICATED PARTS & ASSEMBLIES

RLE Systems can take your design concept and using computer software can program all manufacturing operations to optimize material utilization. We cut numerous profiles for assemblies such as these to maximize every sheet of material for a variety of gauges.

We can provide hardware insertion and finishing services to achieve the desired cosmetic appearance and functionality as required by the customer. Powdercoating, wet painting or electroplating also provide corrosion resistance and desired appearance. Each part is then inspected for quality to ensure accuracy and performance.

FABRICATION SERVICES

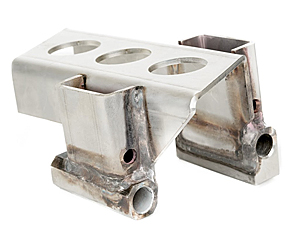

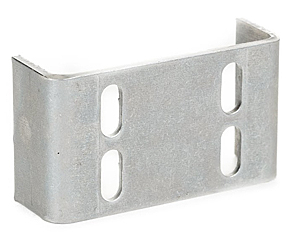

From the moment you engage RLE systems to visualize your concepts and ideas we will utilize computer aided design to realize these ideas into a usable drawing. We can also receive your existing drawings in almost any format. We use software modelling to ensure that all of your sheet metal fabrication needs can be transformed into a usable product without any wasted time and money.

We work with a variety of materials and gauges to cut and form parts to your exact requirements and close tolerances. Hardware insertion and assembly can be performed in designated cells to add value. Finishing services cosmetically enhance appearance and protection desired by the customer. Powdercoating, wet painting or electroplating all provide corrosion resistance and customized appearance.

We can also receive your existing drawings in almost any format. We use software modelling to ensure that all of your sheet metal fabrication needs can be transformed into a usable product without any wasted time and money.

We also utilize MRP software to plan and track jobs as they progress at every stage. We manage the entire process from initial concept to a quality inspected first article and onward to production.Computer controlled services include:- Laser Cutting

- CNC Forming

- CNC Punching

- CNC Machining

- Certified MIG, TIG & Spot Welding

We work with a variety of materials and gauges to cut and form parts to your exact requirements and close tolerances. Hardware insertion and assembly can be performed in designated cells to add value. Finishing services cosmetically enhance appearance and protection desired by the customer. Powdercoating, wet painting or electroplating all provide corrosion resistance and customized appearance.