What We Do

Whether your objective is to introduce bold, market-disrupting innovation or simply to enhance an existing product, RLE Systems has the skills and resources to help you realize your goals.

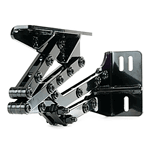

We provide hardware insertion and finishing services to achieve the desired cosmetic appearance and functionality required. Powder-coating, wet painting and electroplating are offered to achieve the corrosion resistance and/or desired appearance. Each part is inspected for quality to ensure accuracy and performance.

We work with a variety of materials and gauges to cut and form parts to your exact requirements and close tolerances. Hardware insertion and assembly can be performed to add value. Finishing services cosmetically enhance appearance and provide protection. Powder-coating, wet painting or electroplating all provide corrosion resistance and customized appearance.

MRP software is utilized to plan and track jobs as they progress at every stage. The entire process is tightly managed from initial concept to a quality-inspected first article to finished production goods.

CNC services include:

- Laser Cutting

- CNC Forming

- CNC Punching

- CNC Machining

- Certified MIG, TIG & Spot Welding

Our team of engineers and production specialists work closely with each customer to design and develop the fluid control solution that fits their needs. Existing products can be tailored to meet specific application requirements but unlike others who can offer only what is on their shelf, the RLE approach starts with you in-mind.

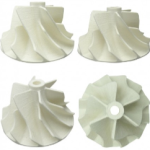

Our 3D printing service allows us to accelerate design ideas into functional products for proof of concept and onward to production.

Our 3D printing service allows us to accelerate design ideas into functional products for proof of concept and onward to production.

When you can not only visualize a product but can feel it, you can gain a better understanding of its operation before spending large sums of money of tooling and fixtures. Design changes can be incorporated quickly and affordably without complex and costly tooling changes.

When you can not only visualize a product but can feel it, you can gain a better understanding of its operation before spending large sums of money of tooling and fixtures. Design changes can be incorporated quickly and affordably without complex and costly tooling changes.

Your route to market can shorten to maximize revenue and minimize lead time.

For more robust applications manufactured from specific materials, we utilize our CNC milling & turning facilities. These facilities, geared for low-volume production, allow us to cost-effectively prototype a unit (or multiple units) for full-function operation and test. Where assembly is required, our designated work cells can assemble and test to desired standards. This offers a cost effective method to produce complex parts in low volumes without expensive tooling and fixtures.

For more robust applications manufactured from specific materials, we utilize our CNC milling & turning facilities. These facilities, geared for low-volume production, allow us to cost-effectively prototype a unit (or multiple units) for full-function operation and test. Where assembly is required, our designated work cells can assemble and test to desired standards. This offers a cost effective method to produce complex parts in low volumes without expensive tooling and fixtures. Our designated environmental test facility offers reliable testing from -103°F to 392°F (-75°C to 200°C). This allows us to rigorously test components in the most arduous of conditions to simulate and exceed conditions in the field of service.

Our designated environmental test facility offers reliable testing from -103°F to 392°F (-75°C to 200°C). This allows us to rigorously test components in the most arduous of conditions to simulate and exceed conditions in the field of service.

610-518-3751

610-518-3751